Add to Cart

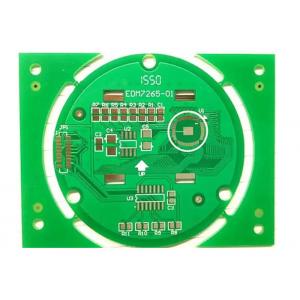

Double-sided PCB board is a very important PCB board in the circuit board, the market has double-sided circuit board metal base PCB board, Hi-Tg heavy copper foil circuit board, flat winding double-sided circuit board, high frequency PCB, mixed dielectric base high frequency double-sided circuit board, etc. It is suitable for a wide range of high-tech industries such as: telecommunications, power supply, computer, industrial control, digital products, scientific and educational instruments, medical instruments, automobiles, aerospace defense and so on.

The difference between double-sided PCB board and single-sided PCB board is that the single-panel circuit is only on one side of the PCB board, while the double-sided PCB circuit can be in the two sides of the PCB board, with holes in the middle to connect the double-sided PCB board circuit. Parameters of double-sided PCB board In addition to the production process of double-sided PCB board is different from that of single-sided PCB board, there is also a copper sinking process, that is, the process of double-sided circuit conduction.

| Copper Thickness | 1oz~3oz,0.5-5 Oz |

| Board Thickness | 1.6mm, 0.5~3.2mm, 0.2-3.0mm, 0.3~2.5mm, 2.0mm |

| Min. Hole Size | 0.25mm, 0.1mm, 0.2 Mm, 0.15-0.2mm, 0.1mm-1mm |

| Min. Line Spacing | 0.003", 4mil, 0.2mm, 0.15mm, 0.1mm4mil) |

| Application | Electronics Device, Consumer Electronics, Electronical Products, Industrial, And So On |

| Layer | 1~20 Layers, 1-24layers |

| Base Material | FR4, Aluminium, TG, Rogers, CEM-1 |

| Min. Line Width | 3mi, 4mil, 0.1mm, 0.1mm(Flash Gold)/0.15mm(HASL), 0.1 0mm |

| Surface Finishing | HASL, OSP, ENIG, HASL Lead Free, Immersion Gold |

| Product Name | Printed Circuit Board, 94V0 PCB Design / PCB Manufacturing |

| Solder Mask | Blue, Green. Red. Blue. White. Black.Yellow, Green/black/white/red/blue Etc., |

| Rohs | Lead free |

| Turnkey PCBA | PCB+components sourcing+assembly+package | ||||

| Assembly details | SMT and Thru-hole, ISO lines | ||||

| Lead Time | Prototype: 15 work days. Mass order: 20~25 work days | ||||

| Testing on products | Flying Probe Test, X-ray Inspection, AOI Test, functional test | ||||

| Quantity | Min quantity: 1pcs. Prototype, small order, mass order, all OK | ||||

| Files we need | PCB: Gerber files(CAM, PCB, PCBDOC) | ||||

| Files we need | Components: Bill of Materials(BOM list) | ||||

| Files we need | Assembly: Pick-N-Place file | ||||

| PCB panel Size | Min size: 0.25*0.25 inches(6*6mm) | ||||

| Max size: 20*20 inches(500*500mm) | |||||

| PCB Solder Type | Water Soluble Solder Paste, RoHS lead free | ||||

| Components details | Passive Down to 0201 size | ||||

| Components details | BGA and VFBGA | ||||

| Components details | Leadless Chip Carriers/CSP | ||||

| Components details | Double-sided SMT Assembly | ||||

| Components details | Fine Pitch to 0.8mils | ||||

| Components details | BGA Repair and Reball | ||||

| Components details | Part Removal and Replacement | ||||

| Component package | Cut Tape,Tube,Reels,Loose Parts | ||||

| PCB assembly | Drilling-----Exposure-----Plating-----Etaching & Stripping-----Punching-----Electrical Testing-----SMT-----Wave Soldering-----Assembling-----ICT-----Function Testing-----Temperature & Humidity Testing | ||||

Our Advantages:

1. Program and functional test and package by Free.

2. High quality: IPC-A-610E standard, E-test, X-ray, AOI test, QC, 100% functional test.

3. Professional service: PCB/FPC/Aluminium Making, SMT, DIP, Component Sourcing, OEM with 21 years experience.

4. Certifications: UL, 94v-0, CE, SGS, FCC, RoHS, ISO9001, ISO14001,IATF16949

Kerongda is a PCB manufacturer, providing turnkey and partial turnkey printed circuit board assembly services.We can produce customized PCB board and PCBA for you ,PCB solder mask color ,material, thickness etc... all can be chosed as your demands.